Creating and managing remedials

Remedials allow you to track defects and re-makes, by creating a secondary record linked to the original defective order.

Video Guide

Creating a remedial

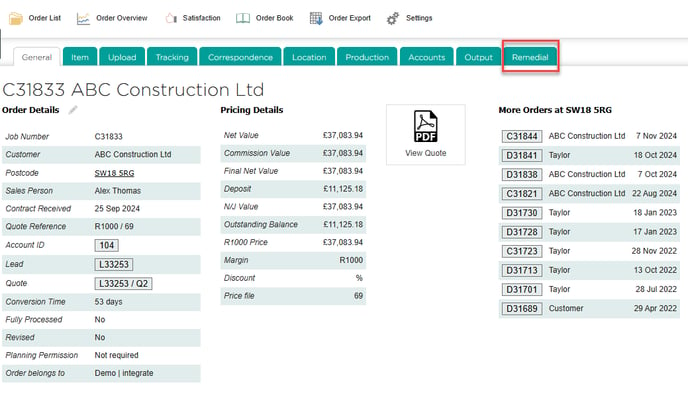

- To create a remedial, go to the defective order, and then click on the Remedial tab.

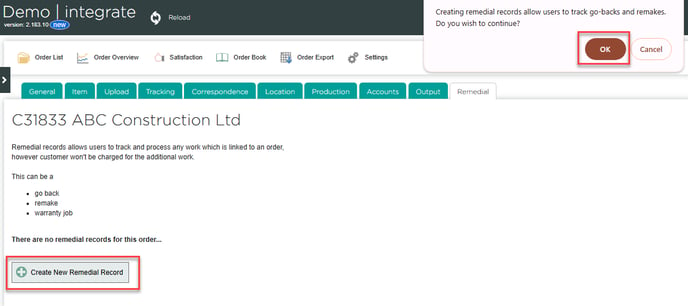

- Click Create New Remedial Record, then OK.

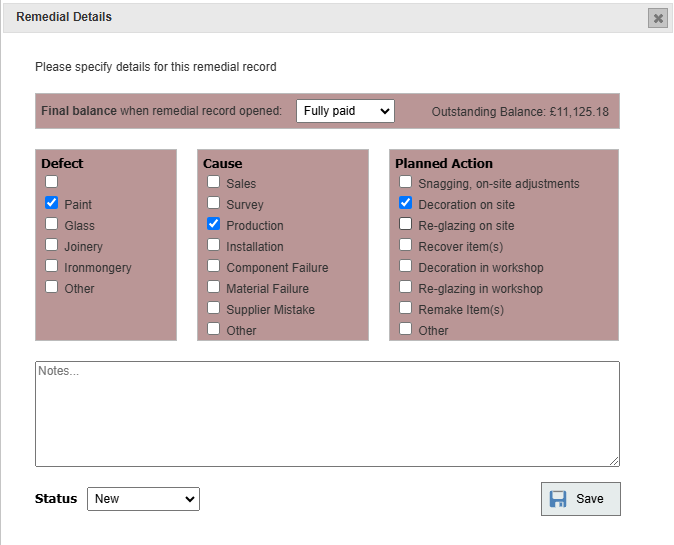

- Record the defect, cause, and planned action, along with whether the final balance for the order has been paid yet. Click Save.

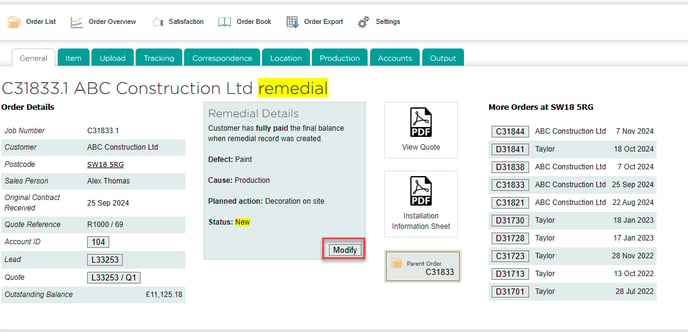

- A record for the remedial will be created, which will have the order number of the original order followed by a decimal point. To make changes, including to mark the remedial as completed, click the Modify button.

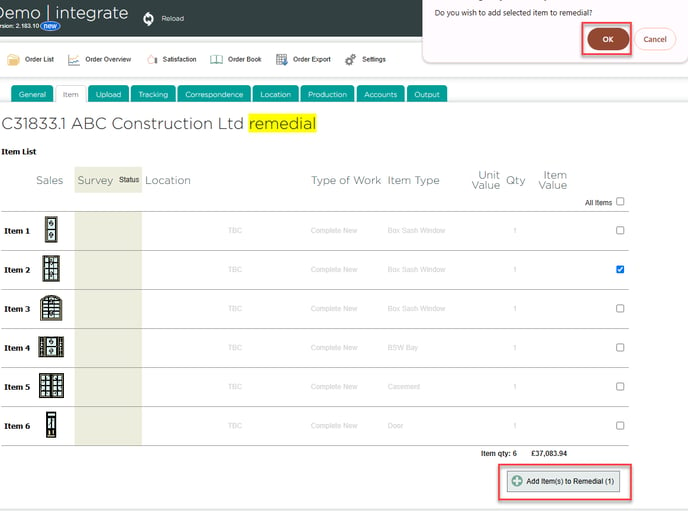

- To survey items for a remedial, click the Item tab. Tick one or more of the items and then click Add Item(s) to Remedial and OK.

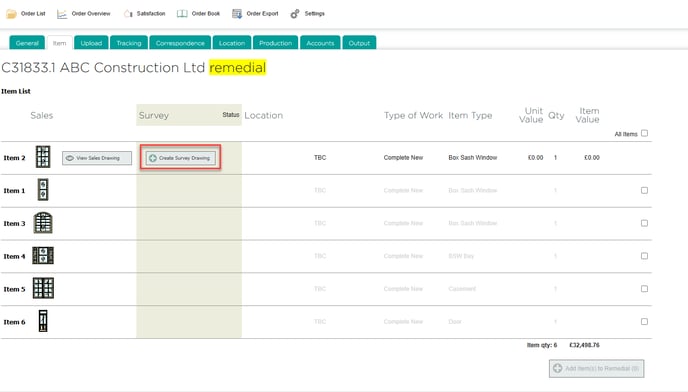

- You can then click Create Survey Drawing for each item on the remedial.

- This will open Drawing Board, allowing you to specify the repairs for each remedial item. For more on this, see the separate guide on Repairs.

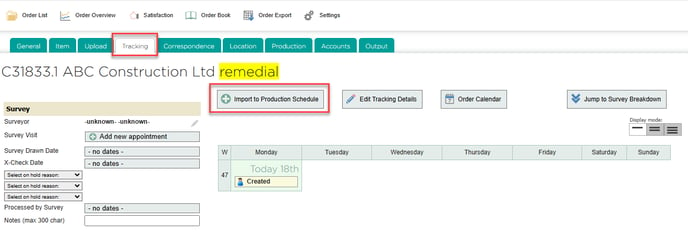

- Remedial jobs can be imported into the Production Schedule from within the Tracking tab, just like regular jobs.

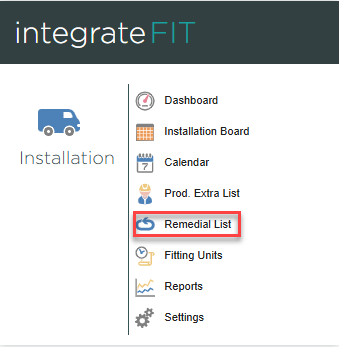

- To view a list of all remedials, click the Remedial List button under the integrateFIT module.