How to Configure Frame and Sash Sectional Details

Setting up sectional details, especially for rebated frames/sashes, is not self explanatory. This document aims to help with configuration, clarifying reference points when deciding on finished and unfinished sizes.

Finished vs unfinished sizes

This terminology comes from the early days of the system, also referred to as jamb and profiled jamb sizes.

The following two terminologies are used

-

finished frame = unfinished frame + stop size -

jamb = profiled jamb + machined out from jamb

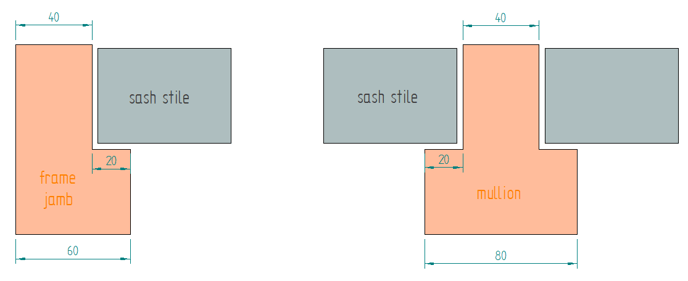

While the former is used for frames with plant on stops, the latter refers to solid profiled frames. In both cases the end result is the same. The example below shows the simplest scenario:

40mm unfinished frame, 20mm stop size, simple frame & sash shapes.

Traditional / heritage sections

Example 1

Back end works with unfinished frame & stop size, and calculates finished frame on front end.

Properties to be configured on Default Values page to achieve details in our example.

-png.png?width=354&height=162&name=unnamed%20(1)-png.png)

-png.png?width=363&height=114&name=unnamed%20(2)-png.png)

Flush casement & door with multiple rebates

The first example showed the simplest case possible. In order to achieve better insulation however, companies make their frames and sashes with multiple rebates, so the actual sectional details can get way more complicated. It is crucial to obtain the key measurements correctly when configuring Default Values.

Example 2

-png.png?width=688&height=302&name=unnamed%20(3)-png.png)

This example is closer to modern high performance window and door sections.

These complicated shapes can be translated to integrate’s details by following the steps below.

-

Get bounding rectangle of sash stile (in Example 2 it is 70mm)

-

Get clearance around sash at the point where sash stile was obtained (in Example 2 it is 5mm)

-

Input these as per image below

-png.png?width=484&height=184&name=unnamed%20(4)-png.png)

Frame measurements are a consequence of sash details above.

-

Unfinished frame jamb size to is be obtained where sash stile & clearance were recorded (in Example 2 it is 30mm)

-

Similarly unfinished mullion size to be taken where sash stile & clearance were recorded (in Example 2 it is 20mm)

-

Stop size can be calculated based on unfinished and finished sizes. Please note, since frame jambs and mullions are machined using the same cutter, the result of these two calculations should be the same. (in Example 2 these are both 30mm)

-

frame stop size = finished frame jamb - unfinished frame jamb -

mullion stop size = finished mullion - unfinished mullion

-

Input these as per image below

-png-1.png?width=360&height=148&name=unnamed%20(5)-png-1.png)

-png.png?width=359&height=141&name=unnamed%20(6)-png.png)

Please note, by obtaining measurements this way, the visual appearance on the drawing will also be correct.

Assuming that The item in Example 2 is an opening out casement, when looking at the finished product externally, the customer will see a 20mm mullion with 5mm clearance and 70mm sash stile. To oversimplify slightly, we do not care what is in the middle, we are only interested in the internal and external faces of the item.

Storm proof windows

Storm proof items in integrate are opening out casements where sash overlaps the frame externally.

Operations available are the same as flush casements

![]()

The following example shows a modern storm proof section. When obtaining the key measurements, it is important to select the right reference points from the reference CAD drawing.

-png.png?width=688&height=318&name=unnamed%20(8)-png.png)

Frame sizes

We look at the external face of the frame, which is 38mm in our example. This is the reference point where we split the frame to unfinished & stop sizes. The sum of these will give us the finished frame jamb (58mm), which is the internal face of the frame.

-png.png?width=331&height=163&name=unnamed%20(9)-png.png)

Once stop size is determined, unfinished mullion size can be calculated, since we know that the same profiler cutter is used both for frame jamb and mullion (so stop sizes are the same).

Sash sizes

We keep looking further at the external face of the frame and we can obtain the clearance between frame and sash there, in the example this is 5mm. This is our second reference point, where we split the sash to stile + overlap (58 + 12mm).

-png.png?width=471&height=221&name=unnamed%20(10)-png.png)

By setting these details correctly, our glass sightline sizes will be correct.

Tilt & Turn Windows

Tilt and turn items in integrate are opening in casements where sash overlaps the frame internally.

Operations specific to tilt and turn casements: Bottom Left and Bottom Right

![]()

The following example shows a modern tilt and turn section. When obtaining the key measurements, it is important to select the right reference points from the customer’s CAD drawing.

-png.png?width=688&height=240&name=unnamed%20(12)-png.png)

Frame sizes

We look at the internal face of the frame, which is 40mm in our example. This is the reference point where we split the frame to unfinished & stop sizes. The sum of these will give us the finished frame jamb (75mm), which is the external face of the frame.

-png-1.png?width=347&height=158&name=unnamed%20(13)-png-1.png)

Once stop size is determined, unfinished mullion size can be calculated, since we know that the same profiler cutter is used both for frame jamb and mullion (so stop sizes are the same).

Sash sizes

We keep looking further at the internal face of the frame and we can obtain the clearance between frame and sash there, in the example this is 10mm. This is our second reference point, where we split the sash to stile + overlap (55 + 15mm).

-png.png?width=469&height=222&name=unnamed%20(14)-png.png)

By setting these details correctly, our glass sightline sizes will be correct.

Slope on transoms

To be described

Cill details

To be described